What are MEP plans? And why you might need them

What is am MEP in construction?

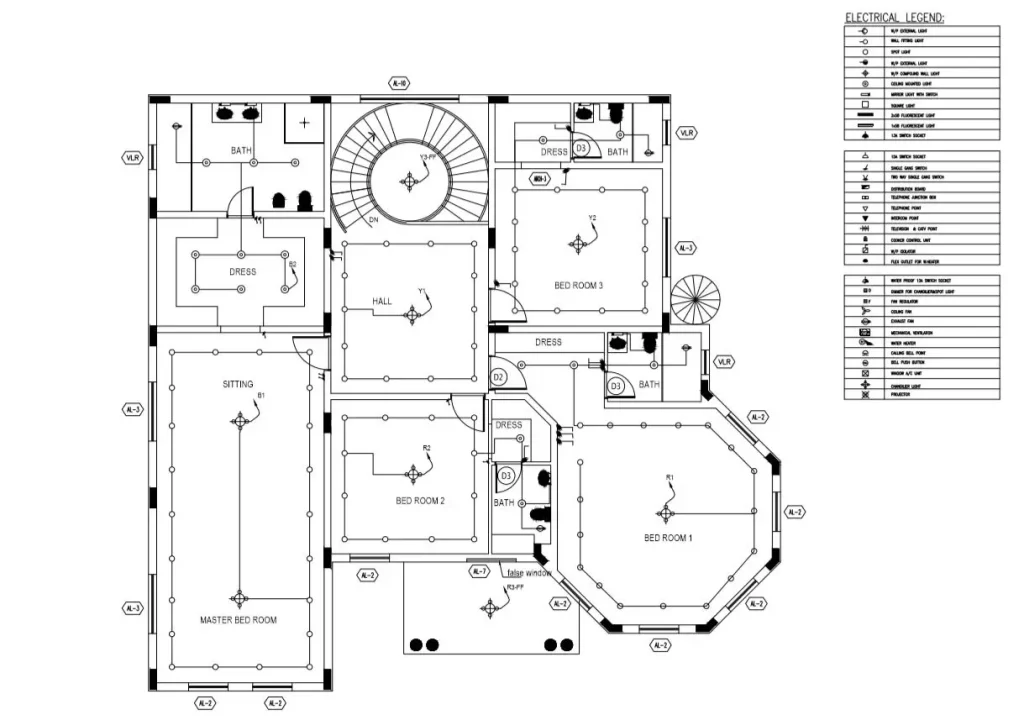

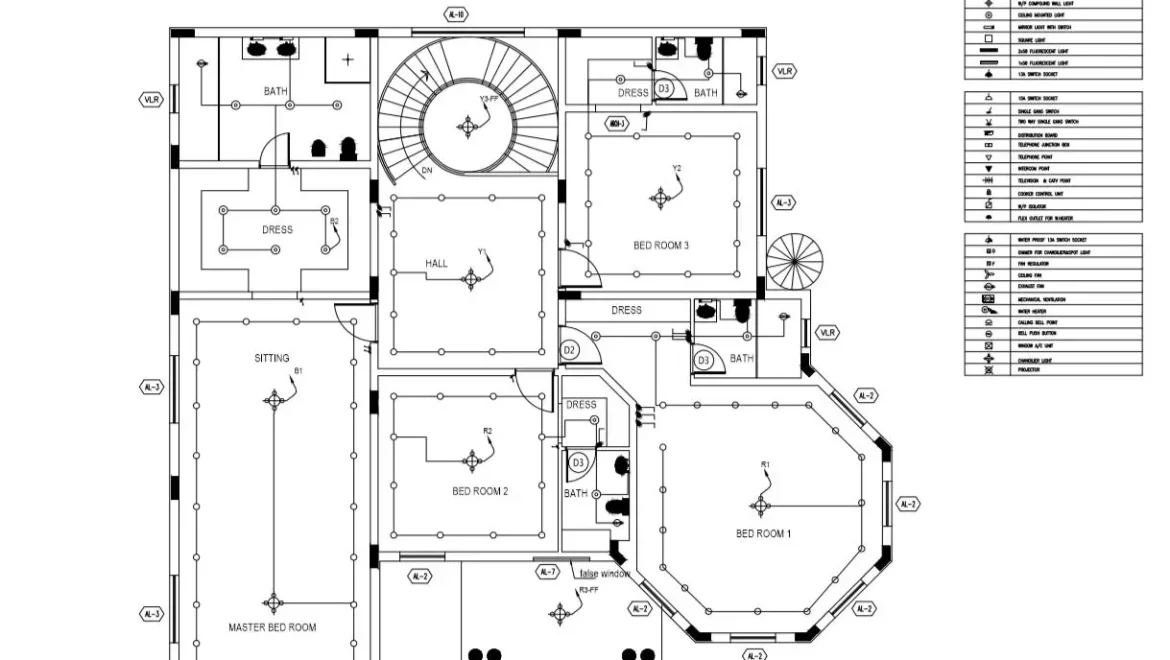

MEP stands for mechanical, electrical and plumbing. MEP engineering is the science and are of planning, designing and managing the MEP systems of a building.

- M – the mechanical design elements of a property, such as the heating and cooling system are important because they make the inside comfortable. This makes it so you can live in buildings in all weather conditions, hot and cold.

- E – the electrical system keeps all the lights and power going, it also powers the other systems. Architectural lighting plans are key component of the electrical engineering process.

- P – finally, the plumbing system provides fresh water for cleaning, drinking etc. They also take storm and wastewater safely away.

What’s in MEP drawings?

These types of drawings are created by combining architectural, structural, and civil shop drawing for a project. These types of drawings smooth out the manufacturing, installation, assembly and maintenance of the MEP in a building. Contractors use these drawings to get precise specifications and identify faults before construction starts.

The drawings provide construction cost saving approximately 30%, along with the improvement in the building delivery schedules to over 40%.

Benefits of using a MEP engineering company –

Working with an experienced MEP engineering company has several benefits:

- It can optimize material needs to lower installation costs while maintaining excellent performance and code compliance.

- Because of the high level of interaction between MEP systems, they are usually built jointly. This unified approach eliminates equipment collisions, prevalent during the separate building of mechanical, electrical, and plumbing systems separately.

- Joint designs enable the effective utilization of space.

What is the importance of the drawings?

Furthermore, they provide important systems of checks and balances during the construction phase of a project. The purpose is to ensure the end result keeps to the design shown in the construction documents, and meets the expectations of the owner.